A magneto ignition switch is connected – When it comes to ignition systems, the magneto ignition switch holds a pivotal role. This comprehensive guide delves into the intricate details of a magneto ignition switch, from its electrical circuitry and switch components to its installation, troubleshooting, and safety considerations.

Prepare to embark on an illuminating journey into the world of magneto ignition switches.

As we delve into the complexities of a magneto ignition switch, we will unravel its electrical circuit, examining the role of the ignition coil and the intricate wiring configuration that brings the system to life. We will also dissect the switch’s key components, exploring their functions and the safety features that ensure reliable operation.

1. Circuitry and Wiring

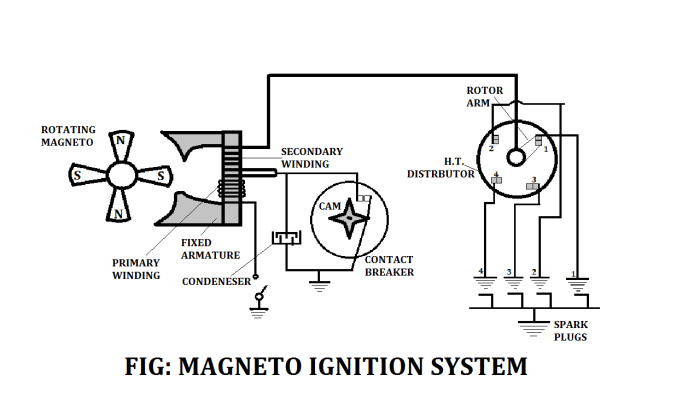

When a magneto ignition switch is connected, it completes an electrical circuit that provides power to the ignition coil. The ignition coil then generates a high-voltage spark that ignites the fuel in the engine’s cylinders.

The wiring configuration for connecting a magneto ignition switch to the ignition system typically involves connecting the switch to the battery, the ignition coil, and the spark plugs. The specific wiring diagram will vary depending on the type of magneto ignition switch and the engine it is being used with.

2. Switch Components and Function

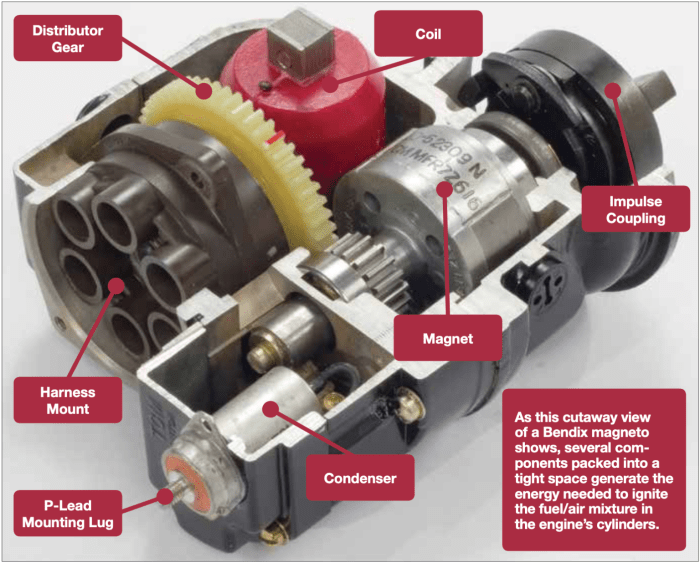

The key components of a magneto ignition switch include the switch body, the contacts, the actuator, and the terminals. The switch body houses the other components and provides insulation between the electrical terminals.

The contacts are the conductive elements that open and close the circuit when the switch is operated. The actuator is the part of the switch that is moved to open or close the contacts.

3. Installation and Maintenance

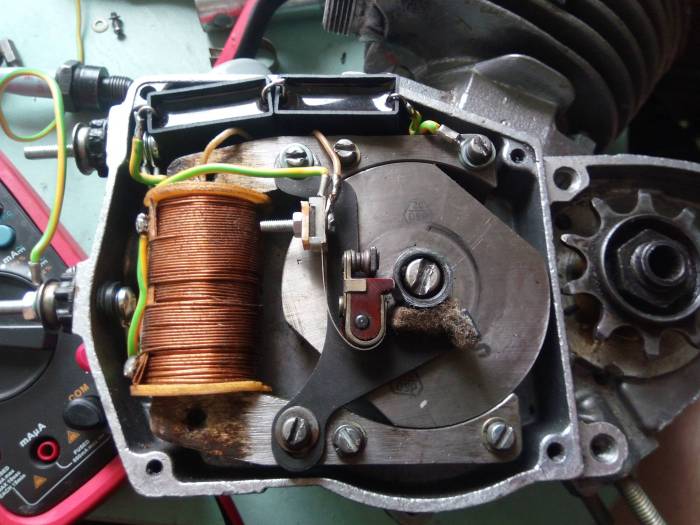

To install a magneto ignition switch, it is important to follow the manufacturer’s instructions carefully. The switch should be mounted in a location that is protected from moisture and vibration.

The electrical connections should be made using the proper torque specifications. Loose connections can cause the switch to malfunction or overheat.

4. Troubleshooting

Common symptoms of a faulty magneto ignition switch include engine misfires, difficulty starting the engine, and no spark at the spark plugs.

To diagnose a faulty magneto ignition switch, it is important to check the electrical connections and the switch itself. The switch can be tested using a multimeter to check for continuity.

5. Applications and Advantages: A Magneto Ignition Switch Is Connected

Magneto ignition switches are used in a variety of applications, including small engines, motorcycles, and marine engines.

Advantages of using magneto ignition switches include their simplicity, reliability, and low cost.

6. Safety Considerations

It is important to follow safety precautions when working with magneto ignition switches. The switch should be disconnected from the battery before performing any maintenance or repairs.

It is also important to avoid touching the electrical terminals of the switch, as this can cause an electrical shock.

Common Queries

What is the primary function of a magneto ignition switch?

A magneto ignition switch acts as a central control point, responsible for opening and closing the electrical circuit that supplies power to the ignition system.

What are the key components of a magneto ignition switch?

The main components include the switch housing, terminals, contacts, rotor, and a mechanism for actuating the switch.

How do I troubleshoot a faulty magneto ignition switch?

Common troubleshooting steps involve checking for loose connections, damaged wiring, or a faulty switch mechanism. Using a multimeter to test for continuity and voltage can also aid in identifying the issue.